SB series

SB-16III

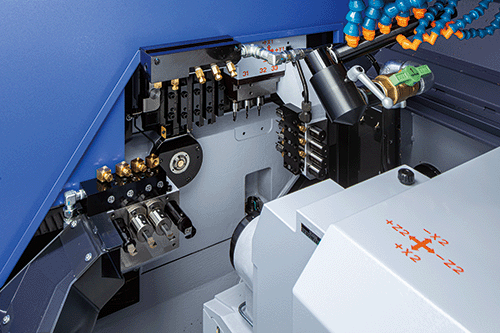

Achieving both sufficient functionality and the minimum necessary size

- Max.machining diameter

- Tool Post

- Max.headstock stroke

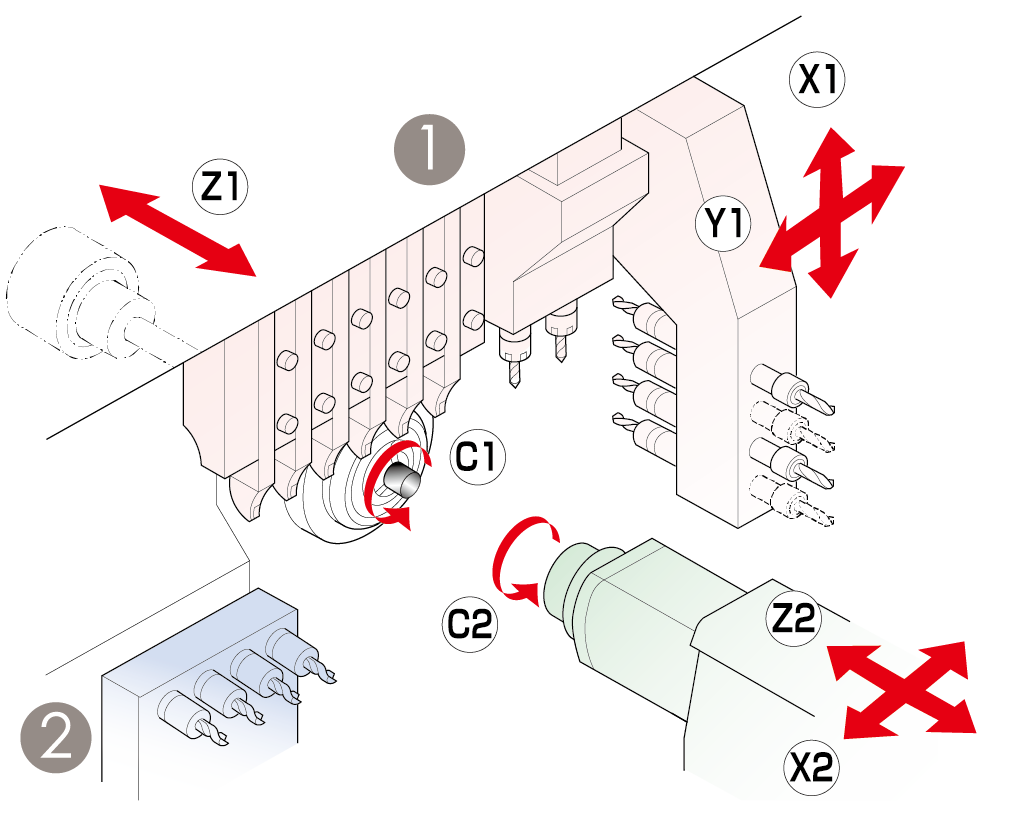

| Tool Post | Tooling | ||

|---|---|---|---|

| ① |

2-Spindle cross drilling unit  |

Turning tool(□12mm) | 6 tools |

| Front-end working tool | 4 tools | ||

| Rear-end working tool | 4 tools | ||

| Power-driven tool | 2 tools | ||

|

3-Spindle cross drilling unit  |

Turning tool(□12mm) | 5 tools | |

| Front-end working tool | 4 tools | ||

| Rear-end working tool | 4 tools | ||

| Power-driven tool | 3 tools | ||

|

3-Spindle cross drilling unit  |

Turning tool(□10mm) | 6 tools | |

| Front-end working tool | 4本 | ||

| Rear-end working tool | 4 tools | ||

| Power-driven tool | 4 tools | ||

| ② |

|

Rear-end working tool (Stationary tool) |

3 tools |

| Item | SB-16III | ||

|---|---|---|---|

| Max.machining diameter | ø 16mm | ||

| Max.headstock stroke | Stationary G.B. | 205mm | |

| Revolving G.B. | 155mm | ||

| Number of turning tools | 6 tools(□12mm) / OP:5 tools(□12mm) / OP:6 tools(□10mm) | ||

| 4-spindle sleeve holder |

Number of tools | Front:4 tools | |

| Rear :4 tools | |||

| Max.drilling capability | ø 10mm | ||

| Max.tapping capability | M8 × P1.25 | ||

| Power-driven att. | Number of tools | 2tools/OP:3tools | |

| Max.drilling capability | ø 6mm | ||

| Max.tapping capability | ER16 | M5×P0.8 | |

| ER11 | M3×P0.5 | ||

| Spindle speed | ER16 | max.5,000min-1 | |

| ER11 | max.7,500min-1 | ||

| Drive motor | 0.5kw | ||

| Rapid feed rate | 35m/min (X1,Y1,Z1,X2,Z2) | ||

| Main spindle indexing angle | C-axis control/OP:15° | ||

| Main spindle speed | max.10,000min-1 | ||

| Main spindle motor | 2.2kw(Continuous) / 3.7kw(15min./60%ED) | ||

| Dimensions (W×D×H) | 1,861 × 1,060 × 1,750mm | ||

| Weight | 1,700kg | ||

| Power consumption | 3.0KVA | ||

| Item | SB-16III | ||

|---|---|---|---|

| Max.chucking diameter | ø 16mm | ||

| Max.length for front ejection | 80mm | ||

| Max.work projection length | 30mm | ||

| 4-spindle | Max.work projection length | 4 tools | |

| backworking | Max.drilling capability | ø 8mm | |

| unit | Max.tapping capability | M6 x P1.0 | |

| Sub spindle indexing angle | C-axis control | ||

| Sub spindle speed | max.9,000min-1 | ||

| Sub spindle motor | 0.55kw(Continuous) | ||

| / 1.1kw(15min./40%ED) | |||

Standard Accessories and Functions

- CNC unit FANUC 0i-TF Pius

- Operation panel 10.4-inch color LCD display

- Pneumatic unit

- Coolant level detector

- Automatic centralized lubrication unit

- Door interlock system

- Broken cutoff tool detector

- Parts ejection detector

- Drive unit for revolving guide bush

- Revolving guide bush unit

- Main/Sub collet

- C-axis control (Main/Sub)

- Gang-type tool holder for fixed 6 tools 12mm)

- 2-spindle cross drilling unit (for ER11 or ER16)

- 4-spindle sleeve holder

- Back 4-Spindle unit

- Air purge for revolving guide bush

- Sub spindle air purge unit

- Sub spindle air blow unit

- I/O module extension unit

- Terminal block

- Work light

- Leakage breaker

Optional Accessories and Functions

- Coolant flow detector

- Water removal unit

- Beacon

- Chip conveyor

- Parts conveyor

- Parts receptacle in the machine

- Parts separator unit A

- Parts ejector (Air cylinder type)

- Parts ejector with guide tube

- Parts stopper unit

- Spindle indexing 15° type (main spindle)

- Main spindle inner tube

- Sub spindle clamping device

- Revolving magic guide bush unit

- Gang-type tool holder 10mm×6 tools, ☐ 12mm×5 tools)

- Gang-type tool holder for coolant through tool 12mm×5 tools / 12mm×6 tools)

- 3-spindle cross drilling unit for ER11

- 3-spindle cross drilling unit for ER11/16

- 3-spindle cross drilling unit for ER16

- Coolant unit 2.5MPa

- Coolant unit signal cable

- Coolant unit power cable

- Coolant valve

- Coolant pipings

- Automatic bar feeder interface

- LAN/RS232C interface

- Transformer

- Manual pulse generator

MACHINE SERIES

- SB series

- SB-12RG

- SB-16III

- SB-20R typeG

- SB-20RII

- SR series

- SR-10J typeC

- SR-20JII

- SR-32JIII

- SR-38 typeB

- Other series

- SL-7/10

- SW-12RII

- SP-20

- SW-20

- SV-20R

- ST-20

- SD-26 typeS

- SD-26 typeG/E/C

- SX-38

- ST-38